Products

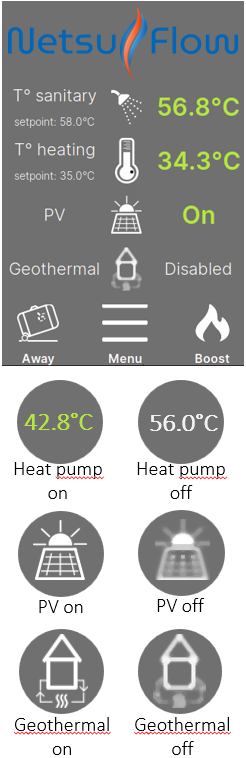

Heat pump controller

HARDWARE

– 32-bit CPU (2MB Ram – 8MB flash) and RTC clock

– 4x PT100 T° sensor, SHT31 I2C humidity sensor

– Thermostat heat/cold

– PV panel signal AC260V

– Highly compressor 700W, Heating resistor 3000W

– 2-way valves and 3-way valves support

– Hot gas defrost control

– PWM fan

– 3,5” or bigger TFT colour display with capacitive touchscreen

– Connectivity via Wi-Fi, Bluetooth, Modbus, USB

SOFTWARE

– Full support of all features of the hardware

– Logic based on configurable rules (truth table in CSV format)

– Parameters via configuration file

– Away and Boost functions

– Control photovoltaic & geothermal

– Log mechanism

– Multilingual GUI

Download characteristics

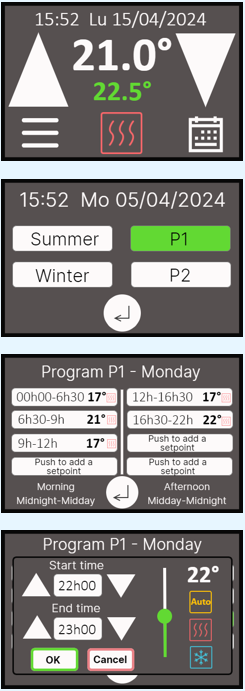

Room thermostat

HARDWARE

– Standard 24VAC power, accepts 9 to 30V AC

– Drives heat pump, boiler, ventilation system, or any circuit through its 2 relays that allow up to 230VAC/2A max

– Measure of ambient T° and humidity

– Modes heat/cold/off

– 3,5” or bigger TFT colour display with capacitive touchscreen

– Optional connectivity: Wi-Fi Matter, RF, Modbus and OpenTherm

– Optional sensors: CO² and VOCs

SOFTWARE

– Configurable parameters such as min. & max. T° via config. file

– Multilingual GUI

– Programmable: up to 4 programs (summer, winter, 2 customs)

Download characteristics

Energy Management System – Coming soon

HARDWARE

– Main board with 32 bit processor capable to drive wired devices via deported relays, Modbus and photovoltaic signal

– Up to 1024 devices via child boards connected to the main board

– Custom cabinet, ventilated and reinforced power

– 11” touchscreen colour display

SOFTWARE

– Interface, via API’s, to predictive EMS level 1

– Logic of activation of connected devices based on configurable rules

– Groups assignment based on type of devices and location

– Customizable dashboards & alerts to monitor the status and the activities of the system

– Log mechanism – function to export in CSV

– SQL database

Use case

Development of district heat networks based on renewable energy, and/or heat recovery, is accelerating in many European countries to decrease carbon emissions. In addition, the end-user price of this energy is often attractive and makes heat networks more and more popular.

In order to maximize these networks, an Energy Management Systems – EMS in short – can be plugged in to transform electricity into heat, and store it in the network, when the price of the electricity is zero (on-site photovoltaic production) or even negative (excess electricity on the distribution networks).

An EMS is composed of 2 levels: level 1 is responsible to determine when and for how long the “free” electricity is available, and level 2 will drive the components (compressors, thermodynamic water heaters, immersion heaters, etc.) that transform electricity into heat.

The NetsuFlow product is a level 2 EMS that includes electronic equipment that allows interaction with the components that store energy in the form of heat. It comes with software to interface with level 1, to control the logic of all the components and to monitor the entire system.